Tech

Best AC brands in India 2023

An overview of the best AC brands in India 2023, with the production capacity of the company, location of a manufacturing plant, establishment year, pros, cons, and models/series. Further AC buying guide also provided.

In the Summer season, India’s climate become Hot and Humid. and it becomes hard to live in that condition. AC will be a good choice in that condition. It is hard to decide the best AC brands in India 2023 because there are a lot of manufacturers in the Indian market who deals in AC and every manufacturer has a lot of models.

Best AC Brands in India 2023

| Company Name | Year of Establishment | Location of Manufacturing Plant | Production Capacity |

| 1. Samsung India Electronics Pvt. Ltd. | 1995 | Noida, Uttar Pradesh | 200,000 units/year |

| 2. Godrej Appliances | 1958 | Shirwal, Maharashtra | 150,000 units/year |

| 3. Whirlpool India Ltd | 1911 | Pune, Maharashtra | 200,000 units/year |

| 4. Voltas Limited | 1954 | Dadra and Nagar Haveli | 1.5 million units/year |

| 5. Blue Star Limited | 1943 | Himachal Pradesh | 1.2 million units/year |

| 6. Daikin Airconditioning India Pvt. Ltd. | 2000 | Neemrana, Rajasthan | 1 million units/year |

| 7. LG Electronics India Pvt. Ltd. | 1997 | Greater Noida, Uttar Pradesh | 500,000 units/year |

| 8. Carrier Airconditioning & Refrigeration Ltd | 1988 | Gurgaon, Haryana | 400,000 units/year |

| 9. Panasonic India Pvt. Ltd. | 1972 | Jhajjar, Haryana | 350,000 units/year |

| 10. Hitachi Home & Life Solutions (India) Ltd | 1984 | Kadi, Gujarat | 300,000 units/year |

| 11. Mitsubishi Electric India Pvt. Ltd. | 1952 | Pune, Maharashtra | 100,000 units/year |

Further, we will discuss the above company’s models/series in the market, Pros, and Cons:

1. Samsung India Electronics Pvt. Ltd.

Pros

- Advanced technology

- good after-sales service

- wide product range

Cons

- Relatively expensive

- mixed reviews about product quality

Available Model

- 3 Star

- 5 Star

- Inverter ACs

- AR Series

- Wind-Free Serie

2. Godrej Appliances

Pros

- Affordable products

- energy-efficient models

- good after-sales service

Cons

- Limited product range

Available Model

- 3 Star

- 5 Star

- Inverter ACs

- NXW

- GIC Series

3. Whirlpool India Ltd

Pros

- Affordable products

- good after-sales service.

Cons

- Limited product range

- lower build quality compared to some other brands

Available Model

- 3 Star

- 5 Star

- Inverter ACs

- Magicool

- 3D Cool Series

4. Voltas Limited

Pros

- Advanced technology

- good after-sales service

- wide product range

Cons

- Relatively expensive

- mixed reviews about product quality

Available Model

- 3 Star

- 5 Star

- Inverter ACs

- AR Series

- Wind-Free Serie

5. Blue Star Limited

Pros

- Durable and reliable products,

- energy-efficient models

- good after-sales service.

Cons

- Relatively expensive

- limited product range

Available Model

- 3 Star

- 5 Star

- Inverter ACs

6. Daikin Airconditioning India Pvt. Ltd.

Pros

- Energy-efficient models

- advanced technology

- high-quality products

Cons

- Relatively expensive

- limited after-sales service.

Available Model

- 3 Star

- 5 Star

- Inverter ACs

- AR Series

- Wind-Free Serie

7. LG Electronics India Pvt. Ltd.

Pros

- Affordable products

- energy-efficient models

- good after-sales service

Cons

- Limited product range

- lower build quality compared to some other brands.

Available Model

- 3 Star

- 5 Star

- Inverter ACs

- KS-Q Series.

8. Carrier Airconditioning & Refrigeration Ltd

Pros

- High-quality products

- energy-efficient models

- good after-sales service.

Cons

- Relatively expensive

- limited product range

Available Model

- 3 Star

- 5 Star

- Inverter ACs

- Superia

- Estrella

- Midea Series

9. Panasonic India Pvt. Ltd.

Pros

- Energy-efficient models

- advanced technology

- high-quality products.

Cons

- Limited after-sales service

- relatively expensive

Available Model

- 3 Star

- 5 Star

- Inverter ACs

- CS/CU-KU Series

10. Hitachi Home & Life Solutions (India) Ltd

Pros

- Energy-efficient models

- advanced technology

- good after-sales service

Cons

- Relatively expensive

- limited product range

Available Model

- 3 Star

- 5 Star

- Inverter ACs

- Kashikoi

- iConnect Series

11. Mitsubishi Electric India Pvt. Ltd.

Pros

- Energy-efficient models

- advanced technology

- high-quality products.

Cons

- Relatively expensive

- limited after-sales service.

Available Model

- 3 Star

- 5 Star

- Inverter ACs

- MSY-GN Series

AC Buying Guide: How to choose the best AC?

It’s important to note that the choice of the best AC brands in India 2023 and model for you depends on various factors such as room size, budget, features required, and personal preferences.

1. Budget ( Select Split or Window AC )

First and main factor before buying an AC it is important to select a budget range. For the low Price, have to go for window AC otherwise choose Split AC. Split AC is more powerful, and energy-efficient to cool than window AC. Window AC is a single unit whereas Split AC compressor is separate so window AC is noisier than split AC.

2. Room Size and other factors

For determining AC capacity, for effective cooling or space it is important to consider room size, ceiling height of room, door, and windows of the room. For Basic conditions Capacity of AC as Room size will be as follows:

| Room Size | AC Capacity |

| Up to 100 sq. ft | 0.75 Ton AC |

| 100 to 150 sq. ft | 1 ton AC |

| 150 to 250 sq. ft | 1.5 ton AC |

| 250 to 400 sq. ft | 2 ton AC |

Read Also : E-waste Management In India : Effects, Challenges and Solution

FAQs

Which AC is better 3 stars or 5 stars?

when compared initial cost of AC 3 Star will be cheap in price as compared to 5 stars. But 3-star AC consumes more electricity. So if your use duration is very low then you can buy 3-star AC, otherwise, 5-star AC will be more economical to buy as a long-term consideration, because of low electricity consumption.

Which is the best AC brand in India 2023 that provides the best after-sale service?

Samsung and Voltas have approx all over India service centers. But you can check city-wise service before going to buy any brand AC.

It’s always recommended to consult with an AC professional or refer to the manufacturer’s guidelines for the specific model of AC being considered. Choosing an AC with the right capacity for your room can not only provide effective cooling but also help save energy and reduce electricity bills. In the next article, we will discuss specific AC feature models and preferences.

Business

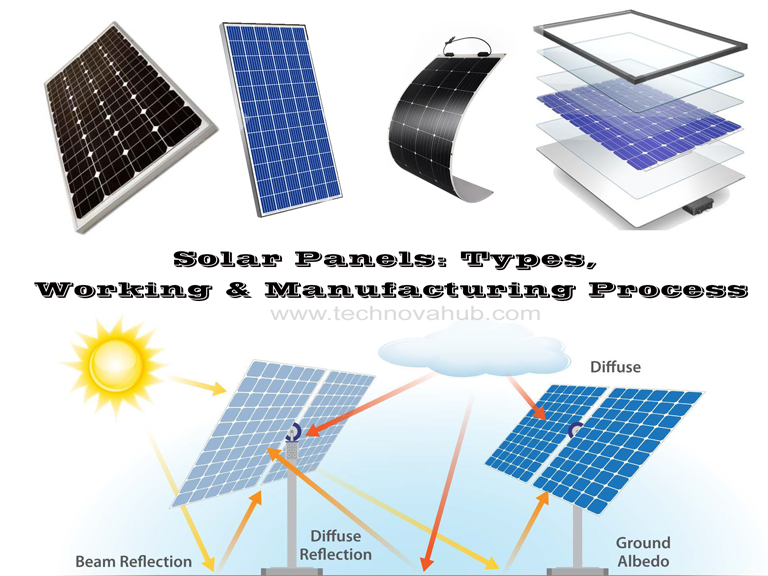

Solar Panels: 3 Types, Working & Manufacturing Process

Solar panels are used to generate electricity by solar energy. Solar panels are a combined formation of solar cells. Solar cells (PV cells) are first developed in 1954, in the United States when Daryl Chapin, Calvin Fuller, and Gerald Pearson at Bell Labs.

The invention of solar cells is a great success in future energy sources for the world.

The main source of solar energy is SUN, which is always available, so solar energy is always available without any other environmental or natural resource disturbance. Solar doesn’t harmful to the environment so it is a Green Energy Resource of energy.

Here we will discuss Only Solar panels. Mainly, the working Process, Types of solar panels, the manufacturing process of solar Panels, and available manufacturing companies in India.

Table of Contents

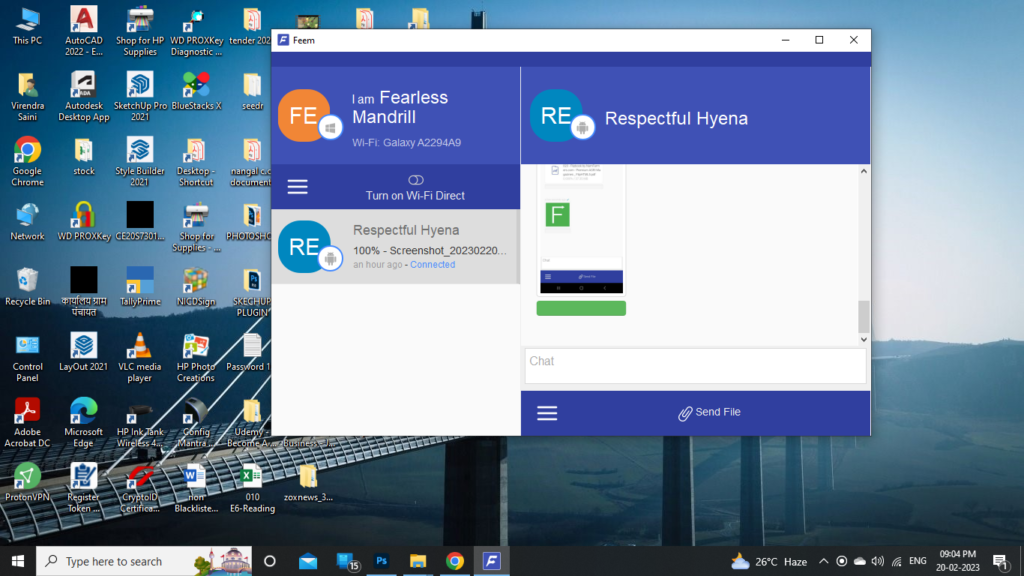

Working Process of Solar cell

A solar cell, also known as a photovoltaic cell, is a device that converts light energy directly into electrical energy. Here is the working process of a solar cell:

The solar cell is made up of semiconductor material, such as silicon, that is designed to absorb photons of sunlight. When sunlight hits the solar cell, the photons are absorbed, exciting the electrons in the semiconductor material.

The excited electrons in the semiconductor material are then able to move freely within the material, creating an electric current.

The electric current generated by the excited electrons is due to the separation of electrons and holes. Holes are the absence of electrons in the semiconductor material. When a photon of sunlight is absorbed, an electron is excited from its normal position and leaves behind a hole.

The solar cell has an electric field that pushes the free electrons toward the top of the cell, while the holes are pushed toward the bottom. This results in the generation of a voltage difference between the top and bottom of the cell, creating an electric potential.

The electric potential generated by the solar cell can be used to power electrical devices or it can be stored in a battery for later use.

A solar cell works by absorbing photons of sunlight and converting the energy into an electric current through the separation of electrons and holes in a semiconductor material.

Manufacturing Process of Solar Cell

The solar cell is made up of a semiconductor material silicon.

First of all, silica sand (Silicon dioxide) is used to extract the Silicon. By the way, Silica is the second most available material on the earth’s crust. Sand with coal melted at 2000 degrees Celsius results in metallurgical-grade silicon with 99% purity. When it solidifies it transforms into a shiny crystal solid.

For the Purity of Silicon further, Liquify the silicon and cleaning by distillation it and depositing it onto a silicon seed sample. Since it is a very difficult process so for this process transformation of everywhere available soil on the earth’s crust into Silicon very heavy and difficult types of machinery requires.

It is deposited into bars and in the next step broken into slices.

Further for the flow of electrons, increase the surface area of the slice top area, development of P-N junction, and collection of electrons next steps done.

Aluminum/Boron in the downward layer and phosphorus in the upper side of the silicon slice are added for the formation of electrons. This process of adding aluminum and phosphorus is called Doping. As result, two different layers are created and in middle, a resistance wall creates which is called the Depletion zone.

by applying a layer of phosphorous to one side of the silicon wafer, and a layer of boron to the other side. This creates a positive and negative charge, which is necessary for the cell to generate electricity when exposed to sunlight.

Manufacturing Process of Solar Panels

A combination of solar cells makes Solar panels.

For Solar Panel manufacturing some manufacturers who start with low investment can purchase Solar cells and by assembling and framing them can be manufacturers of Solar Panels.

Once the solar cells have been created, they are interconnected using metal conductors to form a solar panel. This involves soldering metal ribbons to the top and bottom of each cell and then connecting them together.

The solar cells are then placed between two sheets of glass and sealed with a special adhesive. This creates a protective layer that helps to prevent damage to the cells from weather, moisture, and other environmental factors.

The final step is to assemble the frame for the solar panel. This involves attaching the glass and encapsulated solar cells to a metal frame, which provides support and protection for the panel

Now solar panel has been assembled, it is ready to be tested and then installed for use in a solar energy system.

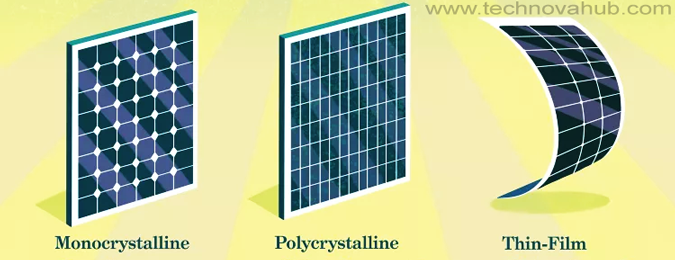

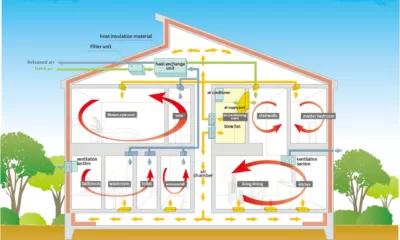

Types of Solar Panels

Solar panels can be classified mainly three types based on efficiency and type of solar cell material used:

- Monocrystalline Solar Panels

- Polycrystalline Solar Panels

- Thin-Film Solar Panels

1. Monocrystalline Solar Panels:

These are made from a single crystal of high-purity silicon, and they are the most efficient type of solar panel. They are also the most expensive to produce solar power. Monocrystalline solar panels are recognizable by their dark, uniform appearance. Solar cells’ shape will not be actually rectangular but all four-corner cut down. It has a maximum efficiency of electricity production. This kind of solar panel can produce electricity in low sunlight or in the cloudy day also.

2. Polycrystalline Solar Panels:

These are made from multiple fragments of silicon melted together to form a single panel. They are less expensive to produce than monocrystalline panels, but they are also slightly less efficient. Polycrystalline solar panels are recognizable by their blue-speckled appearance. Solar cells be rectangular in shape. The efficiency of this kind of solar panel is low compared to Monocrystalline solar panels. It needs high sun rays to produce electricity.

3. Thin-Film Solar Panels:

These are made by depositing layers of semiconductor materials onto a substrate, such as glass or plastic. They are the least expensive to produce, but they are also the least efficient. Thin-film solar panels are recognizable by their uniform, matte appearance and can come in different types including Cadmium Telluride (CdTe), Copper Indium Gallium Selenide (CIGS), and Amorphous Silicon (a-Si). Less used products due to less energy production in large-size solar power plants.

Some other Important Terms:

1. Solar Cell

A solar cell, also known as a photovoltaic cell, is a device that converts sunlight into electricity by the photovoltaic effect. It consists of a thin semiconductor wafer, usually made of silicon, which absorbs photons of light and releases electrons, generating an electric current. Output of one PV cell is approx 0.5V.

2. Solar Module

A solar module is a collection of interconnected solar cells that work together to generate electrical power. The module is enclosed in a protective casing and is designed to withstand outdoor conditions. Generally, 72 cells make a solar module whose output will be 32V.

3. Solar Panel

A solar panel is a flat or angled collection of solar modules that are mounted together on a frame. The panels can be used to generate electricity for a variety of applications, including homes, businesses, and remote locations.

4. Array

A solar array is a collection of multiple solar panels that are connected together to generate electricity. The panels in an array are typically installed on a rooftop or on the ground in a sunny location.

5. Solar Park

A solar park is a large-scale solar power plant that uses a collection of solar panels or arrays to generate electricity. Solar parks can be located in remote areas or integrated into urban environments and can provide electricity to large numbers of homes and businesses.

Biggest Solar Park in World

- Bhadla Solar Park, India (2,245 MW)

- Huanghe Hydropower Hainan Solar Park, China (2,200 MW)

- Pavagada Solar Park, India (2,050 MW)

- Benban Solar Park, Egypt (1,650 MW)

- Tengger Desert Solar Park, China (1,547 MW)

Read Also: Solar Energy: Classification, Components, Advantages, & Disadvantages

What are portable solar panels?

Portable solar panels are small, lightweight solar panels that are designed to be easily transported and used on the go.

They typically consist of a set of solar cells mounted on a flexible or foldable substrate, which can be easily rolled up or folded for storage and transportation.

Portable solar panels are used to generate electricity in remote locations where access to grid electricity is limited or non-existent.

They are commonly used for camping, hiking, and other outdoor activities, as well as for emergency preparedness and disaster relief efforts.

Portable solar panels are available in a variety of sizes and configurations, ranging from small panels that can be used to charge mobile phones and other small devices, to larger panels that can power RVs or boats.

They are often paired with portable battery packs, which can store the electricity generated by the panels for later use.

Portable solar panels are a sustainable and eco-friendly alternative to traditional fuel-powered generators, and they offer the added benefit of being silent and emission-free. They can also help reduce reliance on fossil fuels and decrease carbon emissions.

What are Bifacial Solar Panels?

Bifacial solar panels are a type of solar panel that can generate electricity from both sides of the panel.

They have a transparent back sheet that allows sunlight to pass through to the backside of the solar cells, which can then generate electricity from the reflected and scattered light.

Bifacial solar panels can offer higher energy yields compared to traditional solar panels because they are able to generate electricity from both direct and diffuse sunlight.

Bifacial solar panels are made using similar materials and manufacturing processes as traditional solar panels. However, they typically have a higher upfront cost due to their additional features and increased complexity. Bifacial solar panels can be installed in a similar way to traditional solar panels, either mounted on rooftops or on the ground in solar arrays.

Bifacial solar panels are particularly well-suited for installation in areas with a high albedo, which refers to the reflectivity of the surrounding surfaces.

This includes areas with white or reflective rooftops, snow-covered surfaces, or bodies of water. Bifacial solar panels can also be installed in single-axis or dual-axis tracking systems, which can further increase their energy yield.

How many solar panels do I need?

The number of solar panels you need depends on your consumption of energy and many other factors.

Basically, Look at your energy bills to determine your average daily and monthly energy consumption in kilowatt-hours (kWh).

A typical residential solar system is between 3 kW and 8 kW.

The number of solar panels required will depend on the wattage of the solar panels you plan to use.

For example, a 300-watt solar panel will produce 300 watts of power per hour, and a 5-kW system will require approximately 16-17 solar panels of this size.

Tech

E-waste Management Project: Effects, Challenges, and Solution

In this Digital Era, everyone generates E-waste but no one is aware of E-waste management. we are surrounded by electronic and electric gadgets which are a part of our lifestyle. Today no one can imagine a day without a smartphone or laptop, because these devices are part of our daily life. A software developer can’t do anything without his laptop or computer. And all gadgets have a life after that we have to replace them. For example, a smartphone design life is two to three years after that we have to replace it with another one. And a laptop has a five to six-year design life period after that we have to replace it or some part of it like the battery and fast-running hard disc etc. These Outdated electronic gadgets or machines are called E-waste. And Proper disposal and Management of this E-waste is called E-waste management.

Do you ever think about these outdated products? How are the get disposed and how much harmful are they?

In this article, we will focus on mainly these topics

Table of Contents

1. What is E-waste

E-waste, short for electronic waste, refers to any electronic device or equipment that has reached the end of its useful life and is no longer wanted, and therefore discarded. This can include items such as computers, Laptops, televisions, DVD players, cell phones, refrigerators, washing machines, vacuum cleaners, and other household appliances, as well as electronic toys and other consumer products.

Proper recycling and disposal of E-waste are called E-waste management.

2. Types of E-waste

There are many different types of e-waste, including:

- Computers and peripherals: This includes desktop and laptop computers, keyboards, mice, printers, copiers, fax machines, scanners, and other equipment.

- Mobile devices: This includes cell phones, smartphones, tablets, and other mobile computing devices.

- Entertainment electronics: This includes televisions, gaming consoles, DVD and Blu-ray players, and other entertainment electronics.

- Household appliances: This includes refrigerators, washing machines, dryers, air conditioners, and other household appliances that contain electronic components.

- Medical equipment: This includes electronic medical devices and equipment, such as X-ray machines, MRI machines, and monitors.

- Batteries: This includes rechargeable batteries used in electronics such as laptops, cell phones, and cameras.

3. E-waste by India (yearly report)

India is one of the largest producers of e-waste in the world, with estimates suggesting that the country generates over 2 million metric tonnes of e-waste annually. In 2010 1.8 million metric tonnes of e-waste, and In 2019 3.2 million metric tonnes of e-waste was generated by India. This figure is expected to double by 2025, making India one of the fastest-growing e-waste generators.

Here 70% of e-waste is generated by large-size MNCs, PSUs, Banks, and other public authorities and top Metro cities, and the remaining 30% of e-waste by urban and ruler areas.

The majority of e-waste in India comes from the large and rapidly growing middle class, who often replace electronic devices frequently as they upgrade to newer models. In addition, India is also a hub for the recycling and disposal of e-waste from other countries, particularly developed countries in Europe and North America. For reference news can be checked by indianexpress which shows “29 cases of illegal import of e-waste detected since 2019: Centre tells Parliament”.

4. Effects of Improper E-waste Management on Human health and the environment

Here are some of the ways e-waste can impact health and the environment:

- Human health: When e-waste is not disposed of properly, it can release harmful chemicals and toxins into the environment, which can contaminate soil, air, and water. These chemicals can cause serious health problems for people living in the surrounding areas. For example:

- Lead, mercury, and cadmium can damage the nervous system, kidneys, and liver, high blood pressure low fertility chances, and joint pain.

- Polybrominated diphenyl ethers (PBDEs) used in flame retardants can affect hormone levels, leading to developmental and reproductive problems.

- Phthalates, used in plastics, can cause hormonal imbalances, leading to infertility and other health issues.

- Environment: E-waste also has a significant impact on the environment. Here are some of the effects:

- Landfills: E-waste often ends up in landfills, where it takes up space and can pollute the surrounding environment. Many electronic devices contain heavy metals and other toxins that can leach into the soil and water.

- Air pollution: When e-waste is burned or incinerated, it can release harmful chemicals into the air. This can cause respiratory problems for people living in the surrounding areas.

- Water pollution: Improperly disposed of e-waste can contaminate water sources, such as rivers and streams, with toxic chemicals and heavy metals. This can harm aquatic life and make the water unsafe for drinking or recreation.

5. Challenges for E-waste Management in India

E-waste management in India is an informal sector. In India, poor people and mostly their children collect e-waste which here called by the name “Kabaadiwala”. They work for just a living and have no technical knowledge, so the thing that they can resell like metal they extract in one bundle and plastic in another, and some others remain dumped in a landfill or fires without any knowledge of the environment or soil pollution. In absence of proper guidelines and regulation authority, this E-waste management problem occurs.

Due to the lack of proper awareness and education in India, there is no proper E-waste management. whereas in other developed countries consumers voluntarily donate useless electrical and electronic equipment at formal e-waste recycling centers.

In India, consumers sell e-waste to kabaadiwala whereas in advanced countries consumers have to pay for the proper disposal of the e-waste they generated.

Read Also : Best AC brands in India 2023

6. E-waste Management Methods

By providing proper awareness and education we can reduce E-waste and for recycling purposes, we have to use advanced machinery and methods.

A regulation authority for e-waste management should be responsible for proper disposal rules and regulations. And if required some fines or penalties should be imposed for it.

Now we further point out some methods that are used in other advanced countries for the disposal of E-waste.

- Collection of E-waste at a center or storage house.

- Segregate E-waste by type of E-waste.

- laptop

- Smartphone

- Refrigerator

- Television

- Dismantle one by one by a trained technical person.

- Separate parts

- Reusable like Hard disc, Ram, etc. ( after erasing data which will be ready for resell)

- Repairable parts (smartphone after refurbished will be ready to resell)

- Metallic parts, Plastic Parts for recycling.

- Remain parts that can be recycled like plastic should be sent for further processing.

- other no used parts should be landfill, by choosing a proper landfill location.

7. Conclusion

E-waste management is a great challenge for India in the upcoming years. In urban and rural areas e-waste development is almost 30% but 70% of e-waste is developed by large size companies and public authorities. E-waste is going to be harmful to public health as well as the environment So, regulation authorities should be regulated E-waste and in place of kabadiwala they have to use advanced disposal techniques. And e-waste should be avoided to direct landfill or burn.

“Education and Awareness Can beat Any problem”.

Tech

4 popular Apps for Laptop to Mobile File Transfer

5 Apps that you can use to transfer data wirelessly from your mobile device to your laptop.

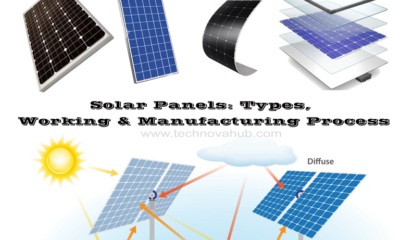

1. Feem

This is the application that should be in every system for someone who transfers large-size files like movies, software, or any other.

| Pros | Cons |

| No Limit | The free version works only for some folders to transfer. |

| Share file Offline | |

| Easy to connect and Use. | |

| No login is required like Airdroid |

Download link Click here

2. SHAREit

This app uses WiFi Direct to transfer files, photos, and videos between your mobile device and laptop. You can also transfer files to other devices that have SHAREit installed. Highly recommended.

| Pros | Cons |

| No Limit | |

| Share file Offline | |

| Easy to connect and Use. | |

| No login is required like Airdroid |

Download link Click here

3. Xender

This app also uses WiFi Direct to transfer files, photos, and videos between your mobile device and laptop. You can also transfer files to other devices that have Xender installed.

| Pros | Cons |

| No Limit | The free version works only for some folders to transfer. |

| Share file Offline | |

| Easy to connect and Use. | |

| No login is required like Airdroid |

Download link Click here

4. AirDroid

This app allows you to transfer files, photos, and videos wirelessly between your mobile device and laptop. You can also send and receive text messages, and manage your device from your laptop.

| Pros | Cons |

| Can be used without setup download by Airdroid web version login. | By Free version can transfer files of less than 30 MB only. |

| Can check mobile contact logs and call in laptop. | Have to Log in First on your Laptop and Mobile. |

Download link Click here

Note: These apps may require you to download the app on both your mobile device and laptop, and some may have limits on the amount of data you can transfer.

-

Business2 years ago

Business2 years agoBhiwadi: An industrial city You Should Know About

-

Uncategorized1 year ago

Uncategorized1 year agoChoosing Best Cement for Paver Block Manufacturing: A Comprehensive Guide

-

Indian Culture2 years ago

Indian Culture2 years agoTop 5 Destinations to Celebrate Holi 2023 in North India

-

Uncategorized1 year ago

Uncategorized1 year agoOptimizing Ventilation and Air Circulation in Architectural Building Design: Enhancing Indoor Comfort and Health

-

Uncategorized2 years ago

Uncategorized2 years agoConcrete blocks: Types, Tests Pros & manufacturing process

-

Business2 years ago

Business2 years agoSolar Panels: 3 Types, Working & Manufacturing Process

-

Tech2 years ago

Tech2 years agoE-waste Management Project: Effects, Challenges, and Solution

-

Tech2 years ago

Tech2 years ago4 popular Apps for Laptop to Mobile File Transfer