Uncategorized

Choosing Best Cement for Paver Block Manufacturing: A Comprehensive Guide

Introduction

Paver blocks are widely used in the construction industry for creating robust and visually appealing outdoor surfaces. The quality and durability of these blocks depend significantly on the type of cement used during the manufacturing process. Selecting the best cement for paver block manufacturing is essential to ensure long-lasting, high-quality products. In this blog, we will explore different types of cement suitable for paver block manufacturing and discuss key factors to consider when choosing the right cement.

Table of Contents

Understanding the Importance of Cement in Paver Block Manufacturing:

Cement plays a critical role in the production of paver blocks, as it acts as a binding agent that holds together the aggregate materials. The right choice of cement ensures the strength, durability, and structural integrity of the paver blocks, making them capable of withstanding heavy loads, harsh weather conditions, and other external factors. Choosing the best cement for paver block manufacturing is vital to achieving top-notch quality and customer satisfaction.

Common Types of Cement for Paver Block Manufacturing:

Ordinary Portland Cement (OPC):

OPC is the most commonly used cement for paver block manufacturing. It is renowned for its excellent strength and durability, making it suitable for heavy-duty applications. OPC is available in different grades, such as 33, 43, and 53, with higher numbers indicating higher strength. The choice of OPC grade depends on the specific requirements of the project.

Generally, OPC-43 cement is used for paver manufacturing.

Important factors for preferred OPC- 43-grade cement in Paver blocks are:

- Good Heat of Hydration: OPC cement has more heat of hydration due to the exothermic reaction of cement and water, so mold of the paver block is released easily due to heat after the concrete is set properly. This process takes almost 24 hours. and no damage to paver blocks occurs.

- Get quick initial strength: OPC grade cement takes strength in almost 14 days while PPC cement takes strength in 28 days. Due to less time to gain strength, it will be available to use in short time period.

- Less water Curing Required

Portland Pozzolana Cement (PPC):

PPC is a blend of OPC and pozzolanic materials like fly ash or silica fumes. It offers improved workability, enhanced resistance to chemical attacks, and reduced heat generation during hydration. PPC is an environmentally friendly option and is ideal for areas with high sulfate content in the soil.

Generally, PPC is not preferred for paver block manufacturing.

Important factors for avoiding PPC in Paver blocks are:

- Less Heat of Hydration: Due to less heat of hydration unmoulding of paver become hard and paver blocks got damaged.

- Take More time to take strength: PPC takes slow initial strength as compared to OPC, so needs to have extra space for storage and needs much amount of money to invest in manufacturing which is not good for business.

- Curing period more than OPC: Due to slow strength gain takes more time to set and has to cure for a long duration.

Portland Slag Cement (PSC):

PSC is produced by blending OPC with granulated blast furnace slag. It provides excellent resistance to chemical attacks, reduces the heat of hydration, and enhances workability. PSC is particularly suitable for paver block manufacturing in areas prone to chemical exposure or where the soil or water contains sulfates.

Factors to Consider When Choosing Cement for Paver Block Manufacturing:

- Strength and Durability: Paver blocks need to withstand heavy loads and various environmental factors. The cement used in manufacturing should possess adequate compressive strength to ensure the longevity and structural integrity of the blocks. Consider the grade of cement (OPC 33, 43, or 53) based on the anticipated load-bearing capacity required for your paver blocks.

- Workability and Setting Time: Workability is a crucial factor during the manufacturing process, as it affects the ease of molding and shaping the paver blocks. The chosen cement should have a balanced setting time, allowing sufficient time for proper compaction and consolidation of the mix. Good workability facilitates better interlocking between the pavers, resulting in a more stable and durable final product.

- Resistance to Water and Chemicals: Paver blocks are exposed to moisture and occasional chemical spills. It is crucial to select cement that exhibits high resistance to water penetration, efflorescence, and chemical attacks. Cement types like PPC and PSC often offer superior resistance in such situations, ensuring the longevity of the paver blocks.

- Cost-effectiveness: Consider the cost of the cement and its availability in your area. While selecting the best cement is important, it should also align with your budget and be readily accessible to ensure a smooth manufacturing process.

Additional Tips for Successful Paver Block Manufacturing:

- Proper Mix Design: Follow the recommended mix proportions provided by the cement manufacturer. Ensure the correct balance of water, aggregates, and cement to achieve the desired consistency and strength of the concrete mix.

- Optimal Curing Process: Proper curing is crucial to attaining optimal strength and durability in paver blocks. Implement a well-defined curing process that includes appropriate moisture retention and curing duration as specified by the cement manufacturer.

- Quality Control: Implement stringent quality control measures during the manufacturing process to ensure consistency in size, shape, and overall quality of the paver blocks. Regular testing and adherence to industry standards will help produce superior products.

Read Also: Container Homes: Moveable, Affordable, and Ecofriendly

Conclusion:

By comparing and detailed explanations of types of cement we can conclude that the Best cement for paver block manufacturing is OPC – 43 grade in all general conditions. Selecting the best cement for paver block manufacturing is essential to ensure the production of durable, high-quality blocks. Consider factors such as strength, workability, resistance to water and chemicals, and cost-effectiveness when making your decision. Collaborate with industry professionals and leverage their expertise to make an informed choice. By using the right cement and following proper manufacturing practices, you can produce paver blocks that excel in strength, durability, and aesthetics.

Uncategorized

11 – Aggregate Test -All Type & Importance

Aggregate test is the most important substance in the construction industry. The strength of the structure after joint strength depends on the strength of the aggregate.

Aggregate indeed plays a crucial role in the construction industry, particularly in the production of concrete. Concrete is a fundamental building material used in various construction projects, and its strength and durability are significantly influenced by the quality of its components, including aggregate.

Required characteristics of aggregate

The study of aggregate can improve the strength of construction as well as money. Here are some key points about the importance of aggregate test in construction:

- Strength and Durability: Aggregates are the primary component in concrete, constituting about 60-75% of the total volume. The properties of the aggregate, such as its strength and durability, directly impact the overall strength and durability of the concrete structure.

- Load-Bearing Capacity: Aggregates provide the bulk and rigidity to concrete, contributing to its load-bearing capacity. The arrangement of aggregates in the mix affects the compressive strength of concrete, which is crucial for supporting structural loads.

- Economy: Properly graded and high-quality aggregates can enhance the workability of concrete mixtures, allowing for more economical use of cement. This is important as cement is typically a more expensive component of concrete. A well-designed mix with the right proportion of aggregate can optimize the use of cement without compromising strength.

- Volume Stability: The expansion and contraction of concrete due to temperature changes and moisture variations can be influenced by the type and quality of aggregate used. Aggregates that are resistant to changes in volume help ensure the long-term stability of the concrete structure.

- Bonding with Cement Paste: The interface between the aggregate particles and the cement paste (the glue that holds concrete together) is critical. Proper bonding is necessary to achieve the desired strength and durability. The surface characteristics of the aggregate can impact this bonding.

- Shape and Size: The shape and size of aggregate particles also play a role. Well-graded aggregates with a variety of sizes can result in a denser and more workable mix. The shape of the particles can affect the surface area and, consequently, the amount of cement paste needed for adequate bonding.

Above all parameters are used to identify aggregate before use on-site in construction.

Type of Aggregate test :

- Particle Size Distribution (Gradation Test):

- Purpose: Determines the distribution of particle sizes within an aggregate sample.

- Method: Sieves of different sizes are used to separate and measure the particles.

- Shape and Texture Tests:

- Flakiness and Elongation Index Test:

- Purpose: Assesses the shape characteristics of aggregate particles.

- Method: Measures the ratio of the elongated or flaky particles to the total mass.

- Angularity Number Test:

- Purpose: Quantifies the angularity of aggregate particles.

- Method: Involves measuring the volume of voids between angular particles.

- Flakiness and Elongation Index Test:

- Specific Gravity and Absorption Test:

- Purpose: Determines the specific gravity and water absorption of the aggregate.

- Method: Involves measuring the weight of the aggregate in air and in water to calculate specific gravity and absorption.

- Bulk Density and Voids Test:

- Purpose: Measures the density and void content of aggregate.

- Method: Involves determining the bulk density and calculating the percentage of voids in the aggregate.

- Soundness Test:

- Purpose: Evaluates the resistance of aggregate to disintegration due to weathering.

- Method: Aggregates are subjected to cycles of wetting and drying in a sodium sulfate or magnesium sulfate solution.

- Los Angeles Abrasion Test:

- Purpose: Measures the resistance of agSogregate to abrasion and impact.

- Method: Aggregates are placed in a drum and rotated, causing abrasion and impact on the particles.

- Crushing Value Test:

- Purpose: Determines the aggregate’s resistance to crushing under a gradually applied compressive load.

- Method: Aggregates are subjected to a specified load and the percentage fines generated is measured.

- Impact Value Test:

- Purpose: Measures the aggregate’s resistance to sudden impact.

- Method: Aggregates are subjected to a standard impact test using a testing machine.

- Moisture Content Test:

- Purpose: Determines the moisture content of aggregates.

- Method: Involves weighing the aggregate before and after drying to calculate the moisture content.

- Alkali Aggregate Reactivity Tests:

- Alkali-Silica Reactivity (ASR) Test: Evaluates the potential of aggregates to react with alkalis in concrete.

- Alkali-Carbonate Reactivity (ACR) Test: Assesses the potential reactivity of carbonate aggregates.

- Organic Impurities Test:

- Purpose: Identifies the presence of organic materials in the aggregate.

- Method: Aggregates are immersed in a solution, and any color change is observed.

IS Code for Aggregate are shown as:

| IS CODE | AGGREGATE TEST |

| IS 2386 – 8 | Methods of Test for Aggregates for Concrete – Petrographic Examination |

| IS 2386-7 | Methods of Test for Aggregates for Concrete, Part VII: Alkali Aggregate Reactivity |

| IS 2386-6 | Methods of test for aggregates for concrete: Measuring mortar making properties of fine aggregates |

| IS 2386-5 | Methods of test for aggregates for concrete: Soundness |

| IS 2386-4 | Methods of test for aggregates for concrete: Mechanical Properties |

| IS 2386-3 | Methods of test for aggregates for concrete: Sp. Gravity, Density, Voids, Bulk Density & Water absorption |

| IS 2386-2 | Methods of test for aggregates for concrete: |

| IS 2386-1 | Methods of test for aggregates for concrete: Particle Size & Shape |

Read Also : Concrete blocks: Types, Tests Pros & manufacturing process

Read also : Most Recommended Is Codes For Aggregates In Construction

Uncategorized

Amazon Sale 2023 : Get prepare for special offers of the year

Amazon sale 2023 date has been announced which we all indian wait of a year for big discounts in shopping.

Upcoming Big sale start from 8 october 2023. Amazon’s flagship event Great Indian Festival will go live on Sunday, Oct 8, with early access for Prime members going live on Saturday, Oct 7 at midnight.

Table of Contents

Some of items price in upcoming sale has been revaled and many item discount price will be available soon.

So, get ready for upcoming shopping season of the year.

Amazon Event Landing Page: Visit Here

Amazon Sale 2023 Shopping Link Categories wise:

- Mobile Phones: Click Here

- Laptops & Smart Watches: Click Here

- Home & Kitchen: Click Here

- Fashion & Beauty: Click Here

- Television & Appliances: Click Here

- Daily Essentials: Click Here

- Amazon Brands: Click Here

- Amazon Devices: Click Here

- Gaming, Books, Personal Care Appliances: Click Here

If you wish to shop before stock out get ready and add items in wishlist before sale starts.

Read Also: Container Homes: Moveable, Affordable, and Ecofriendly

How to choose best deals ?

Amazon price trackers tools

Use Amazon price trackers tools for check best prices with duration it helps in shop in that price of should wait for a price drop.

Some of price tracker tools name are:

1. keepa

2. price history

3. Earny

4. PriceBefore

Check Reviews and Rating

Which item you want to buy, would be purchase by someone before so check product reviews where you can understand about product.

Today’s Deals

Click on “Today’s Deals”, which is dedicated to show special offers and discounts on that time available.

Uncategorized

Concrete mixer machine: Guide to Efficient Mixing Equipment

A concrete mixer machine, also known as a cement mixer, is a device used to combine cement, water, and aggregates (e.g., sand, gravel, or crushed stone) to form concrete. This mixing process ensures that the concrete’s components are evenly distributed and results in a homogenous mixture that is suitable for construction purposes.

Table of Contents

Concrete mixers machine come in various sizes and types, but the most common ones are:

Types of Concrete Mixture Machine

1. Drum Mixer:

This is the most common type of concrete mixer machine, where the ingredients are mixed by tumbling them inside a revolving drum. The drum can be tilted to discharge the concrete. Drum mixers can be further classified as:

- Tilting Drum Mixers: The drum can be tilted to pour the concrete.

- Non-Tilting Drum Mixers: The drum is fixed, and the concrete is discharged by opening a chute at the bottom.

2. Pan Mixer

This type of mixer has a stationary mixing pan and blades that rotate around a vertical axis. The ingredients are mixed as the blades move through the material.

3. Twin Shaft Mixer

This type of mixer has two horizontal shafts with paddles that counter-rotate, ensuring thorough mixing of the materials.

4. Vertical Axis Mixer

In this mixer, the shaft is vertical, and the mixing action is similar to a pan mixer but on a larger scale.

Concrete mixer machines are widely used in various construction projects, including buildings, roads, bridges, and other structures. They are available in different capacities, ranging from small portable mixers suitable for DIY projects to large stationary mixers used in commercial construction.

When operating a concrete mixer machine, it’s essential to follow safety guidelines, wear appropriate protective gear, and ensure that the machine is used and maintained correctly to prevent accidents and ensure optimal performance. Additionally, different types of mixers and concrete formulations may be suitable for specific construction applications, so it’s essential to choose the right equipment and mix design for the project at hand.

Read Also: Best Cement for Paver Block Manufacturing

Reference : Concrete mixer

HOW TO CHOOSE THE RIGHT CONCRETE MIXER machine?

1. Size

Power supply

Durability

portability

Which Concrete Mixture Machine is used Most commonly?

Mostly Drum Mixture machine is used. It is used due to its ease to handle for loading cement, sand, and aggregate as well as unloading concrete. Tilting Drum Mixers are used commonly at small scales. No chute opening is available for unloading, so no cement slurry waste and homogeneous concrete mixture occurs.

What size is to be considered while purchasing a new concrete mixture machine?

When loading and unloading of concrete and material are done by labor manually then choose a capacity of 1.5 bag cement concrete mixture.

What is the price of the RCC Concrete mixer machine?

The concrete Mixture machine costs 50,000 rupees to 2,50,000 rupees. It depends on type of mixture and size of the mixture.

Motor-operated Tilting Drum Mixers costs around 75,000 rupees.

Disclaimer

Please note that the information on technovahub.com is designed to provide general information on the topics presented. The information provided should not be used as a substitute for professional services.

-

Business2 years ago

Business2 years agoBhiwadi: An industrial city You Should Know About

-

Tech2 years ago

Tech2 years agoBest AC brands in India 2023

-

Indian Culture2 years ago

Indian Culture2 years agoTop 5 Destinations to Celebrate Holi 2023 in North India

-

Uncategorized1 year ago

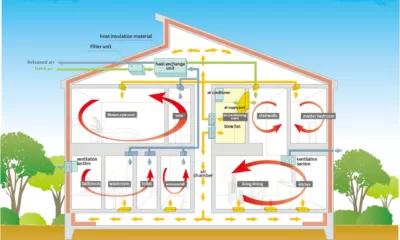

Uncategorized1 year agoOptimizing Ventilation and Air Circulation in Architectural Building Design: Enhancing Indoor Comfort and Health

-

Uncategorized2 years ago

Uncategorized2 years agoConcrete blocks: Types, Tests Pros & manufacturing process

-

Business2 years ago

Business2 years agoSolar Panels: 3 Types, Working & Manufacturing Process

-

Tech2 years ago

Tech2 years agoE-waste Management Project: Effects, Challenges, and Solution

-

Tech2 years ago

Tech2 years ago4 popular Apps for Laptop to Mobile File Transfer